GUSS Safety Vest

Safety is a priority. When crew members wear the GUSS safety vest in the proximity of GUSS, the GUSS driving mechanics are disabled and will not start until the crewmember is clear of the area surrounding the vehicle.

Our new state-of-the-art headquarters and service hub is located in Kingsburg, California — the center of California’s agricultural San Joaquin Valley.

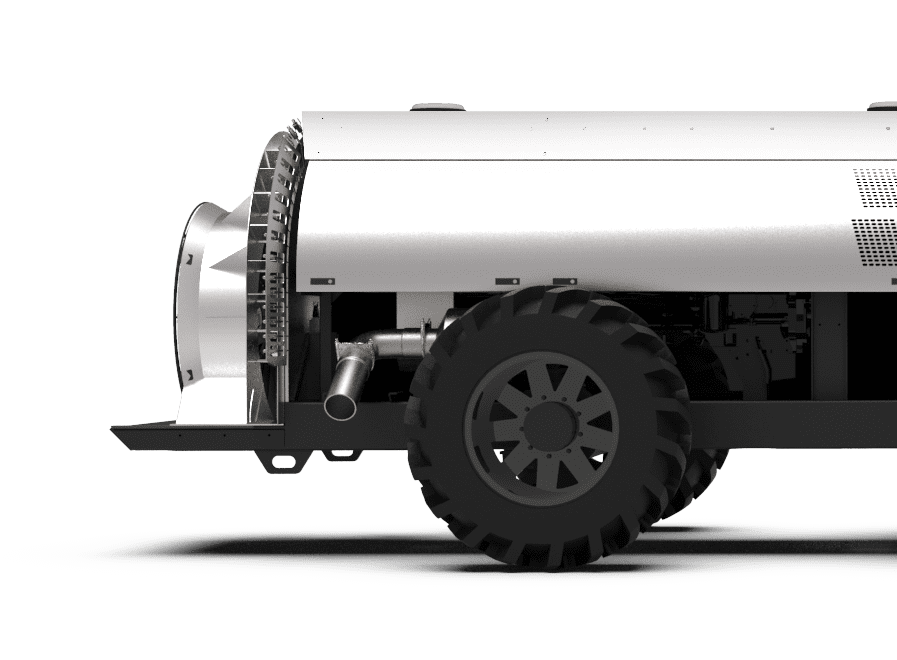

GUSS uses a sophisticated combination of GPS, LiDAR, vehicle sensors, and proprietary software to move through orchards without an onboard operator.

Recent advances have made GPS technology incredibly accurate, but it still doesn’t work well under tree canopies — where GUSS spends much of its time. We developed several additional technologies, vehicle sensors, and software to supplement GPS and guide GUSS safely and efficiently through orchards.

Safety is a priority. When crew members wear the GUSS safety vest in the proximity of GUSS, the GUSS driving mechanics are disabled and will not start until the crewmember is clear of the area surrounding the vehicle.

Increase precision and efficiency as well as lower material costs. Select Spray detects the desired tree and sprays the specific amount of material needed to properly cover every tree, regardless of height or canopy size. This reduces material usage as well as material drift during application.

A single operator can monitor up to 8 GUSS sprayers at a time from the comfort and safety of a pickup truck using a laptop computer. Our user interface provides operators with important sprayer information (position, spray rate, speed, etc.) in real time.

In the event that an issue is detected onboard a sprayer, our interface automatically sends both visual and audible alerts to the operator directing his attention to the exact problem so he can take quick corrective action.